- Home

- Flow Switches, Explosion-proof-flow-switch, Thermal Conductivity Flow Switch

- Product Detail

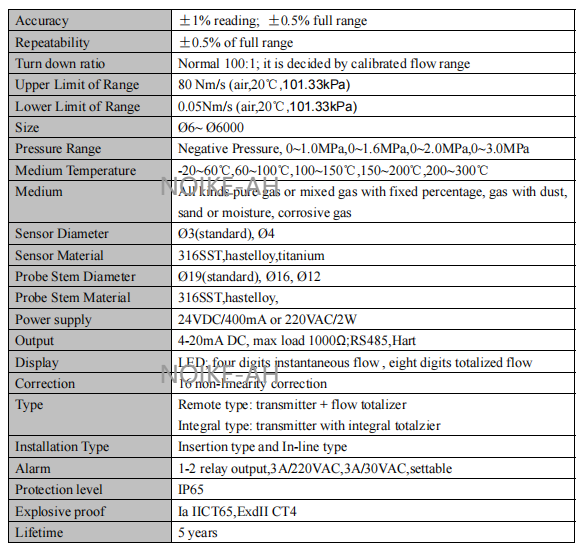

Specification

Overview

The advanced technique of Silver Automation Instruments has been introduced to produce this flow meter measuring gas mass flow. Traditional flow meters need to adopt temperature and pressure compensation for measurement of fluid mass flow, whereas this flow meter can directly measure fluid mass flow without requiring temperature and pressure compensation. Its conspicuous features are as follows: direct trade settlement, no movable components, small pressure loss, wide range ratio, high accuracy, high reliability, simple installation and convenient operation. It is extensively used in the industries such as petroleum, chemical industry, medical industry, heat power plant and environmental protection etc.

Typical Applications

- Flow measurement of gas in industrial pipelines

- Flow measurement of air during gas combustion

- Flow measurement of flue gas out of chimneys

- Flow measurement of waterfall gas during water treatment

- Flow measurement of gas and compressed air during production of cement, cigarette and glass

- Flow measurement of natural gas, coal gas, liquefied gas, flare gas and hydrogen gas etc.

- Flow measurement of trapped gas in steelworks

Operating Principle

NKGF-100Series thermal gas mass flow meter employs thermal diffusion principle. The thermal diffusion technique is that of excellent performance and high reliability under severe conditions.The typical sensing elements include two thermal resistances (platina RTD); one is a velocity sensor and the other is a temperature sensor for automatic compensation for gas temperature variation.

When the two RTDs are placed in medium, the velocity sensor is heated to a constant difference in temperature above ambient temperature, and the temperature sensor is used to

respond to the medium temperature. If gas velocity increases, the heat quantity transmitted to the medium from the sensor will increase, so there is a need for more supply of power, whereas the power for electronic elements to heat RTD is corresponding with mass flow to a certain extent.

Technical Specifications

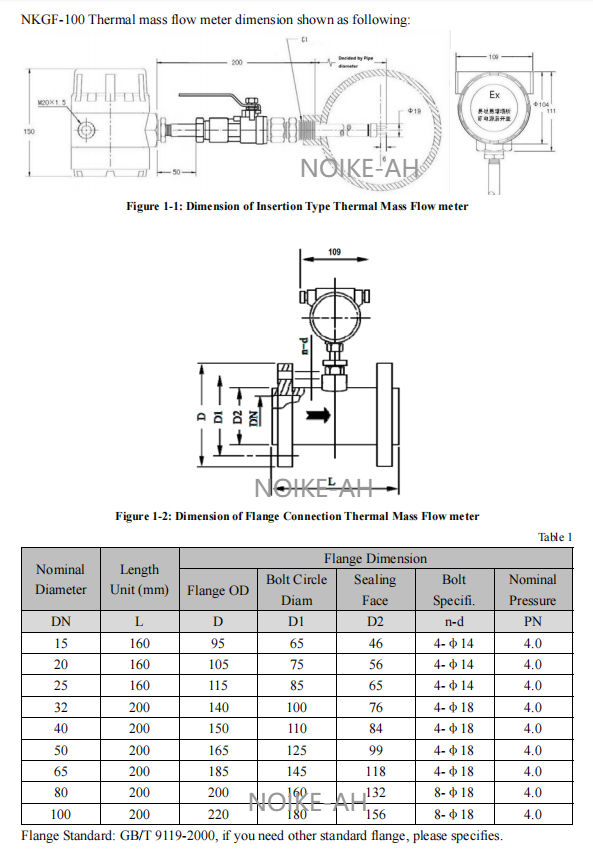

Dimension

Flow range and Flow meter size selection

- Table Reference

Table2: Four kinds common gas calibrated range selection table

Table3: Common gas upper limit

All flow meters are calibrated before leaving factory, the upper limit of flow range will be

indicated on the name plate of flow meter.

- Lower and upper limit of the flow range

1) Lower limit: the thermal mass flow meter is sensitive to low flow, it can detect 0.05 m/s flow

rate, so in normal condition, lower limit can be ignored.

2) Upper limit: It is normally decided by process design; the flow meter upper limit is more than

20% of design limit.

3) Mixed gas measurement: For mixed gas, the ender user should provide standard density and

mole ratio (different gas percentage of the mix gas). The measuring range is decided by our

factory. It is normally calibrated by air or nitrogen, and then corrected by meter conversion

coefficient.

- Statement

The flow range is limited by equipment; please get confirmation from factory before purchasing.

Table of Contents

Talk With Us

- noike009@foxmail.com

- 86 180 5512 0225

- +86(551)-65501008

- Address: 206, Block B, No. 2 Tianda Road, High-tech Zone, Hefei City, Anhui Province, China

- We will respond to you within five minutes.