- Home

- Flowmeters, Gear Flowmeter

- Product Detail

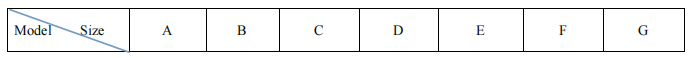

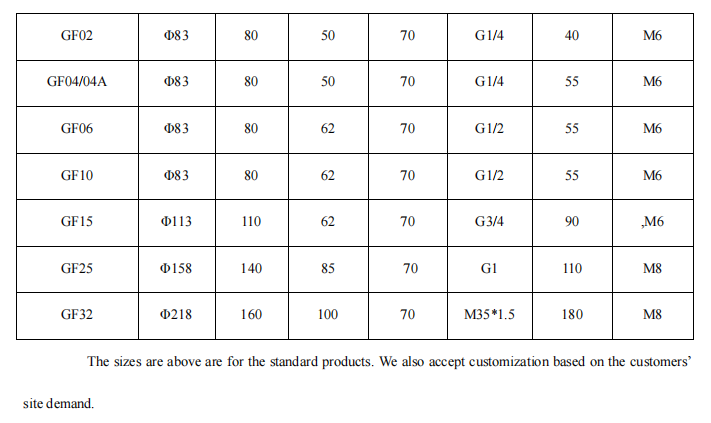

Specification

Product Characteristics

- High voltage resistance (1.0-45MPa)

- High and low temperature resistance (-196℃-200℃)

- Able to measure different kinds of viscous media.

- High precision and repeatability

- Impulse output/Analog output available

- Range ratio width (1: 100)

- Broad range of measurement

- Strong corrosion and pollutant resistance (acid and alkaline)

Scope of Application

- Measurement of resin and glue

- Measurement of hydraulic oil, lubricating oil and grease

- Measurement of fuel oil

- Measurement of printing ink and asphalt

- Measurement of liquid nitrogen, refrigerant and solvent

- Measurement of edible oil, fish oil and food canning

- Measurement of chemical fluid or fluid with corrosion resistance requirements

- Fluid quantitative control system

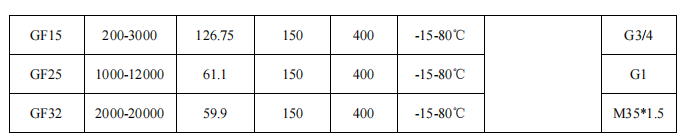

Performance Parameters

Installation Requirements

- The transmitter should be installed in a position that facilitates maintenance and repairing instead of an

environment with high temperature, strong mechanical vibration and strong magnetic field interference and

corrosion.

- The transmitter should be generally installed on the assembly horizontally and firmly with screw. The liquid

direction must be upward once it is installed vertically. The liquid should be filled in the pipeline and bubbles

must be avoided.

- A straight pipe section which is 20 times of the nominal diameter should be set or rectifier should be installed at 9 / 9

the upstream of transmitter while a straight pipe section which is 5 times of the nominal diameter should be set

at the downstream.

- When the transmitter accessories are installed, the base central line should point to the pipe central line and the

gasket at the connected part cannot be inside the liquid.

- Flow regulating valve must be installed at the downstream of the transmitter, if any.

- When transmitter is installed on a new pipe, a filter is suggested to be installed in the upstream of the transmitterto prevent the sundries inside the pipe from entering the transmitter.

- Bypass pipe should be installed near the installation site of the transmitter in order to avoid normal liquidtransmission in course of overhaul.

- The magnetic field near gear flow transmitter and similar interference source may affect the transmitter from collecting signal. The transmitter and display instrument should be connected via the shield cable with metal. Theshielding layer of transmission cable should be earthed at the display instrument site.

Table of Contents

Talk With Us

- noike009@foxmail.com

- 86 180 5512 0225

- +86(551)-65501008

- Address: 206, Block B, No. 2 Tianda Road, High-tech Zone, Hefei City, Anhui Province, China

- We will respond to you within five minutes.